巢湖的PLC可编程控制器技术与应用研究

Research on PLC Programmable Controller Technology and Its Application in Chaohu LakeThis study focuses on the research of PLC programmable controller technology and its application in Chaohu Lake area. The PLC technology is an important part of industrial automation, which has been widely used in various fields such as manufacturing, processing and control systems. This study aims to explore the application of PLC technology in different industries and its potential to improve efficiency and productivity. Through investigating the current situation of PLC technology in Chaohu Lake area, this study also evaluates the challenges and opportunities faced by local industries in adopting this technology. The results of this research provide a theoretical basis and practical guidance for the further development and application of PLC technology in the region.

In recent years, the advancements in technology have revolutionized various industrial sectors, especially in automation and control systems.巢湖, as a focal point for industrial development in China, has also embraced these advancements in the form of Programmable Logic Controllers (PLC). PLCs are computer-based systems that play a pivotal role in automating industrial processes by providing control and monitoring functions. This article delves into the technology behind PLCs and their applications in the industrial landscape of巢湖.

PLC Technology Overview

PLC, or Programmable Logic Controllers, are digital computers designed to perform a wide range of tasks related to automation. They are designed to operate in harsh industrial environments and are capable of monitoring and controlling various processes. PLCs are programmed using a variety of programming languages to execute specific tasks based on input signals from sensors and other devices. The output signals from PLCs control various actuators and machinery to ensure smooth operation of industrial processes.

In巢湖, PLC technology has become an integral part of various industrial sectors such as manufacturing, energy, and infrastructure. The city's industries have adopted PLC systems to enhance productivity, improve efficiency, and reduce operational costs.

PLC in巢湖的工业应用

1. 制造业: 在制造业中,PLC可编程控制器被广泛应用于生产线自动化,它们能够控制复杂的生产流程,包括物料处理、装配、质量检测等环节,通过PLC系统,制造商可以实现对生产过程的实时监控,确保产品质量和生产效率,PLC系统还可以集成先进的控制算法和数据分析工具,帮助制造商优化生产流程,降低成本。

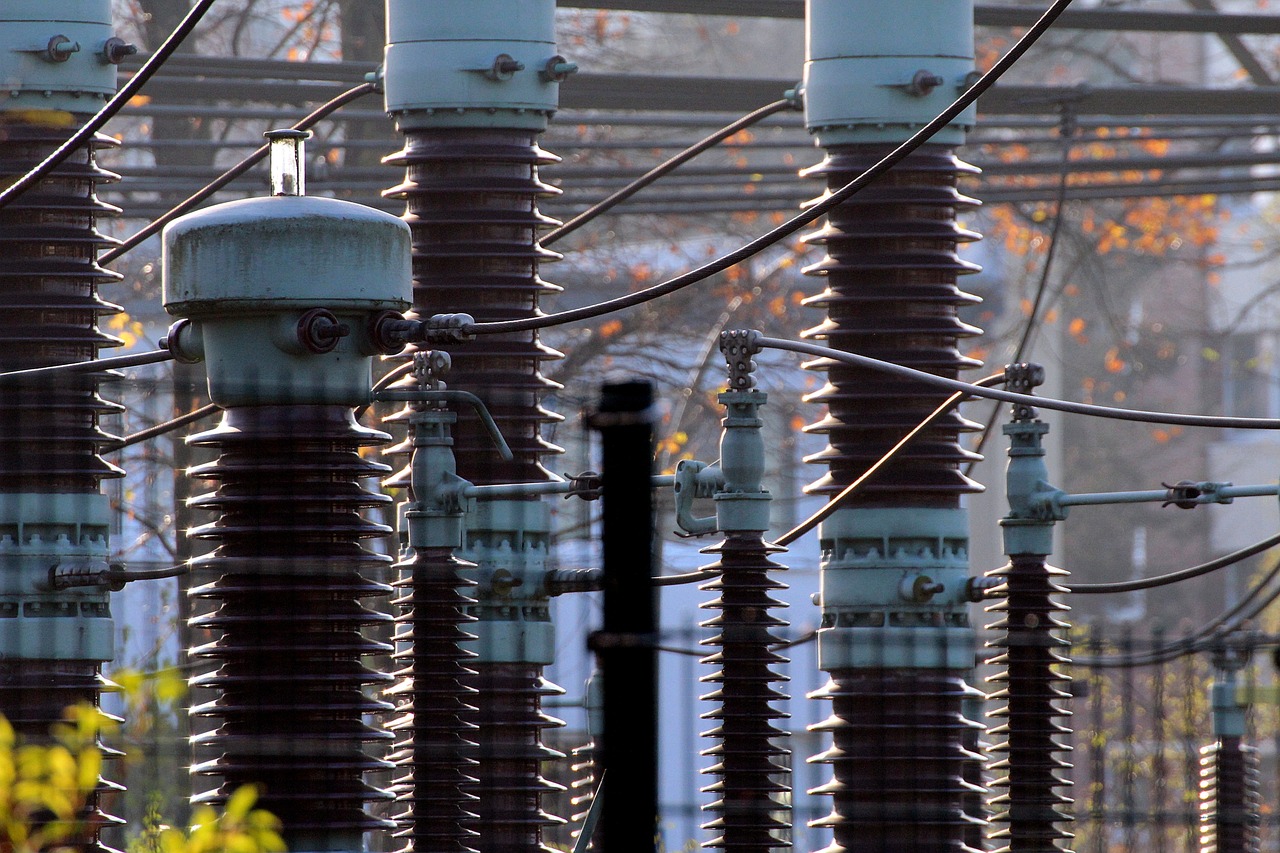

2. 能源行业: 在能源行业,PLC可编程控制器被广泛应用于电力系统监控和控制,它们可以监控电力设备的运行状态,确保电力系统的稳定运行,PLC系统还可以实现能源管理的智能化,通过数据分析帮助能源企业优化能源分配和使用,提高能源利用效率。

3. 基础设施: 在城市基础设施领域,PLC技术也发挥着重要作用,在交通信号灯控制、水处理厂、污水处理厂等场所,PLC系统能够实现自动化控制,提高运营效率和管理水平,PLC系统还可以与物联网技术相结合,实现智能城市的构建。

PLC的优势与挑战

PLC系统的优势在于其可靠性、灵活性和强大的功能,它们能够在恶劣的工业环境中稳定运行,满足各种复杂控制需求,PLC系统还具有高度的灵活性,可以通过编程实现各种复杂的控制逻辑,随着工业4.0的推进和智能制造的快速发展,PLC系统也面临着一些挑战,如网络安全问题、与新兴技术的融合等。

未来展望

随着技术的不断进步,PLC可编程控制器在巢湖及全球工业领域的应用前景广阔,PLC系统将更加注重与其他技术的融合,如物联网、大数据、云计算等,这些技术的结合将为PLC系统带来更多的可能性,使其在智能化、自动化方面发挥更大的作用,随着工业网络安全需求的增加,PLC系统的网络安全性能也将得到进一步提升。

PLC可编程控制器在巢湖的工业发展中扮演着重要角色,随着技术的不断进步和应用领域的拓展,PLC系统将在未来的工业领域中发挥更加重要的作用。

Introduction:

As industrial technology continues its evolution, smart manufacturing has emerged as a cornerstone for enhancing operational efficiency and product quality. One of the key enablers of this revolution is the use of Programmable Logic Controllers (PLCs), which play an integral role in controlling complex machinery and processes. This article delves into the importance of PLCs in modern manufacturing environments and their role in shaping the future of industry-4.0.

Overview of PLCs:

PLCs are computer systems designed to control and monitor industrial automation. Unlike traditional mechanical controllers, PLCs are programmable, allowing for flexible logic and real-time data processing. They are ideal for applications that require precise timing, high reliability, and minimal maintenance. In smart manufacturing, PLCs are instrumental in automating processes such as material handling, assembly lines, and quality inspections, thereby reducing downtime, improving productivity, and increasing customer satisfaction.

The Importance of PLCs in Smart Manufacturing:

1、Automation and Efficiency: PLCs automate routine tasks, reducing the need for manual intervention and minimizing human error. By automating processes, manufacturers can increase production speed, reduce labor costs, and improve overall efficiency.

2、Real-Time Process Control: PLCs provide real-time monitoring and control of manufacturing processes, enabling operators to make immediate adjustments to optimize performance. This leads to better quality control and reduced waste.

3、Modular Design: PLCs can be customized to suit specific manufacturing requirements, making them highly adaptable to various industries. This flexibility allows manufacturers to quickly adjust to changing market demands or technological advancements.

4、Energy Conservation: With the ability to control power consumption precisely, PLCs can help manufacturers save energy while still maintaining high levels of performance. This not only reduces operating costs but also contributes to environmental sustainability.

5、Interoperability: PLCs are often integrated with other industrial systems such as SCADA (Supervisory Control and Data Acquisition) systems and HMI (Human Machine Interface) devices, facilitating communication and data exchange across different systems. This interoperability enables seamless integration of different technologies and streamlines workflows.

6、Security and Compliance: With robust security features, PLCs can help protect against cyber threats and ensure compliance with regulatory requirements. They provide end-to-end protection, from hardware encryption to software updates.

7、Scalability: As demand for automation grows, PLCs offer the potential for scalable solutions. They can be easily upgraded or replaced as technology evolves, making them an ideal choice for evolving manufacturing needs.

Conclusion:

In the era of smart manufacturing, PLCs have emerged as crucial enablers for achieving higher levels of efficiency, productivity, and innovation. By automating processes, providing real-time control, and offering flexibility, PLCs are transforming the way manufacturing operates. As technology advances, PLCs are set to remain a vital component of the industry's future, paving the way for even more sophisticated automation solutions.

Articles related to the knowledge points of this article:

PLC-Based Three-Axis Motor Controller

Mitsubishi PLC Current Controller

Mitsubishi PLC Controller Communication