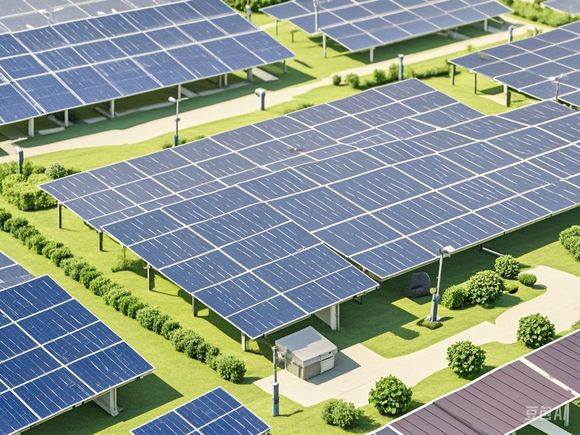

Understanding the Eight Core Materials of Solar PV Modules

Solar PV modules are the heart of solar energy systems, and understanding their core materials is crucial for anyone interested in solar power. Here's a breakdown of the eight key components:1. **Solar Cells**: These are the most important part of the module, made from semiconductor materials like silicon. They absorb sunlight and convert it into electrical energy.2. **Encapsulant**: A clear, protective layer that seals the solar cells and ensures they're protected from the elements. It also helps to enhance light transmission.3. **Backsheet**: This is the back layer of the module that provides structural support and protects the cells from the rear. It's usually made of a durable polymer.4. **Junction Box**: This is where the electrical connections are made. It's responsible for collecting the electricity generated by the solar cells and directing it to the inverter.5. **Frame**: The frame holds the entire module together and provides a mounting structure. It's typically made of aluminum or other strong, lightweight materials.6. **Glass**: The top layer of the module, which is usually made of tempered glass, provides durability and helps to protect the solar cells from damage.7. **EVA (Ethylene Vinyl Acetate)**: This is the glue that holds the solar cells and the glass together, ensuring a secure and weatherproof bond.8. **Adhesive Tape**: Used to attach the junction box to the module and provide additional weatherproofing.Each of these materials plays a vital role in the performance, durability, and efficiency of solar PV modules. Understanding them can help you make informed decisions when considering solar energy for your home or business.

Content:

Hey there! If you're new to the world of solar energy or just looking to brush up on your knowledge, you've come to the right place. Solar photovoltaic (PV) modules are the heart of solar power systems, and they're made up of various materials that work together to convert sunlight into electricity. In this article, we're going to dive into the eight core materials that make up solar PV modules. So, let's get started!

1、Silicon: The Building Block of Solar Cells

Silicon is the primary material used in the production of solar cells. It's abundant, non-toxic, and has excellent electrical properties, making it the perfect choice for converting sunlight into electricity. When sunlight hits a silicon solar cell, it knocks electrons loose, creating an electric current.

2、Aluminum: The Frame and Support Structure

Aluminum is lightweight yet strong, making it ideal for framing solar PV modules. It provides structural support and protects the fragile solar cells from external damage. Aluminum is also used in the module's junction box, which is where the electrical connections are made.

3、Glass: The Protective Cover

The glass used in solar PV modules is specially designed to be ultra-clear and durable. It protects the solar cells from the elements while still allowing maximum sunlight to pass through. Tempered glass is often used because it's strong and can withstand high temperatures and wind loads.

4、EVA (Ethylene Vinyl Acetate): The Encapsulant

EVA is a clear, flexible material that acts as an adhesive and encapsulant for the solar cells. It bonds the glass to the backsheet and the solar cells in between, providing a weatherproof barrier that protects against moisture, dust, and other contaminants.

5、Backsheet: The Rear Layer

The backsheet is the bottom layer of the solar PV module and is designed to protect the solar cells from the backside. It also provides electrical insulation and allows the module to be grounded. Backsheets are typically made of a durable polymer such as Tedlar or a composite material.

6、Copper: The Conductor

Copper is used in the form of wires and ribbons to connect the solar cells together and to the external circuit. It's an excellent conductor of electricity and is resistant to corrosion, ensuring that the electrical connections within the module are reliable and long-lasting.

7、Silver: The Contact Material

Silver is used in the form of paste to make the electrical contact between the solar cells and the copper ribbons. The silver paste is applied to the front and back of the solar cell, creating the front grid and back contacts. Silver's high conductivity is crucial for maximizing the efficiency of the solar cell.

8、Junction Box: The Electrical Interface

The junction box is where the module's electrical connections are made. It's typically made of durable materials like ABS plastic and houses the diodes that prevent power from being wasted when the module is exposed to light in low-power conditions. The junction box also includes connectors that allow the module to be connected to other modules and to the rest of the solar power system.

Now that you have a basic understanding of the eight core materials used in solar PV modules, you can appreciate the complexity and the engineering that goes into these renewable energy powerhouses. Each material plays a crucial role in ensuring the module's durability, efficiency, and safety. As the demand for clean energy continues to grow, the technology behind solar PV modules will continue to evolve, but the fundamental materials will remain the backbone of solar power.

Content expansion reading:

As a foreign trade operator, I'm always on the lookout for the latest and greatest in the world of photovoltaic (PV) modules. Today, I want to highlight eight critical materials that are integral to the production process of high-efficiency solar panels. These ingredients work together to create the power-generating devices we rely on to harness the sun's energy and turn it into usable electricity.

Let's start with silicon, the star of the PV industry. Silicon is a semiconductor material that allows light to enter and exit the solar cell, allowing it to convert sunlight into electricity. Without silicon, there would be no solar panels, which means we wouldn't have access to clean, renewable energy.

Next up is glass, a vital component that serves as the front face of the solar module. It protects the silicon wafer from environmental factors like dust, moisture, and UV rays, ensuring optimal performance and longevity. In addition, glass helps reduce heat absorption, which can improve module efficiency by reducing the need for cooling.

Now let's talk about copper, a metal that plays an essential role in the electrical connections between the cells within the module. Copper is highly conductive, allowing for fast and reliable transmission of electricity between the cells. This makes the entire module function more efficiently, resulting in higher power generation.

Moving on to aluminum, another metal used extensively in PV modules. Aluminum is lightweight and strong, making it ideal for constructing thinner solar panels that require less material but still produce high-quality output. Its low density also reduces the overall weight of the module, improving transportation and installation ease.

We can't overlook polycrystalline silicon, which is produced in thin layers instead of being granular like monocrystalline silicon. Polycrystalline silicon has a lower cost per watt and requires fewer processing steps, making it more economically viable for mass production. However, it may not perform as well as its monocrystalline counterpart in terms of efficiency and durability.

Then there's glass frit, a ceramic material commonly used in manufacturing solar cells because of its excellent thermal conductivity. Glass frit provides a barrier between the cells and prevents heat transfer, maintaining the integrity of the module and enhancing its overall performance.

Moving on to silver paste, a crucial component used in the interconnecting wires that carry electricity between cells. Silver is a noble metal known for its high electrical conductivity and resistance to corrosion, making it an ideal choice for this application. The use of silver paste ensures that each cell receives ample current flow, boosting module efficiency significantly.

Finally, backsheet material is an important factor in preventing dust and moisture from entering the module. It serves as a protective layer that shields the cells from external elements, ensuring their longevity and maintaining optimal performance levels.

In conclusion, these eight materials play a pivotal role in the creation of high-efficiency photovoltaic modules. By prioritizing these components, we can ensure that our solar energy solutions are both reliable and effective, contributing to a cleaner, more sustainable future.

Articles related to the knowledge points of this article:

How Much Does a Small-Scale Solar Power System Cost?

Understanding the Cost of Building a Solar Power Plant

Affordable Solar Power Solutions for Your Home or Business

Solar Power for Your Home: A Guide to Small-Scale Solar Electric Systems

Small-Scale Solar Power Stations: Revolutionize Your Energy Future Today!