Ensuring Safety and Efficiency in Pipeline Monitoring: The Role of Advanced Technology

Keeping an eye on pipelines is crucial for both safety and efficiency. Advanced technology is playing a big role in helping companies do this better than ever before. With sensors and cameras along the pipeline, companies can monitor for leaks, damage, and unusual activity in real-time. This not only helps prevent environmental disasters but also saves money by catching issues early on. Plus, with drones and robots, inspecting hard-to-reach areas is easier and safer. By using data analytics, companies can predict when parts of the pipeline might need maintenance, which helps prevent unexpected shutdowns. Overall, the use of advanced technology is making pipeline monitoring smarter, safer, and more efficient.

Content:

Hey there, fellow professionals in the world of construction and infrastructure! Today, I want to talk about a topic that's super important in our industry: pipeline monitoring. It's not just about keeping an eye on things; it's about ensuring safety, preventing leaks, and maximizing efficiency. And let me tell you, the advancements in technology are taking us to a whole new level.

So, let's dive in and explore how we can use these high-tech tools to keep our pipelines running smoothly and our environment protected. From real-time monitoring systems to AI-powered analytics, we're going to cover it all.

First off, let's talk about the basics. Pipeline monitoring is essentially keeping tabs on the condition and performance of pipelines that carry oil, gas, water, or any other fluid. It's crucial for detecting potential issues before they turn into major disasters. Think about it—a small crack in a pipeline can lead to a big spill, which is bad for business and even worse for the environment.

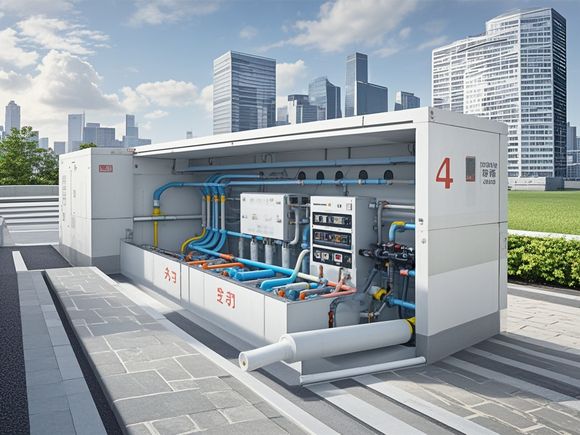

That's where advanced monitoring systems come in. These systems use a variety of sensors to track everything from pressure and temperature to the presence of certain chemicals. With this data, we can quickly identify any anomalies and take action before a problem escalates. It's like having a guardian angel watching over our pipelines, 24/7.

But it's not just about the hardware. Software is just as important. Data analytics and AI are transforming the way we interpret the information gathered by these sensors. Machine learning algorithms can learn to recognize patterns that might indicate an impending failure. This predictive capability is a game-changer, allowing us to be proactive rather than reactive.

Take, for example, a scenario where a pipeline monitoring system detects a gradual increase in pressure. AI can analyze this data and, if it's programmed to do so, can alert operators to take preventative measures. This could be anything from adjusting the flow rate to scheduling maintenance before a rupture occurs. It's all about staying one step ahead of the game.

Another cool aspect of this technology is its ability to integrate with other systems. Imagine a scenario where a monitoring system is connected to a SCADA (Supervisory Control and Data Acquisition) system. This integration allows for remote control and monitoring, which is especially useful in situations where manual inspection is difficult or dangerous.

For instance, in underground or underwater pipelines, sending a team to inspect could be risky. With remote monitoring, we can get a clear picture of what's going on without putting anyone in harm's way. It's all about keeping our workers safe while ensuring the integrity of our infrastructure.

Now, let's talk about the benefits. Implementing advanced pipeline monitoring systems can lead to significant cost savings in the long run. By preventing leaks and minimizing downtime for repairs, we can improve operational efficiency and boost our bottom line. It's a win-win for both the company and the environment.

Moreover, these systems can help us comply with strict environmental regulations. By quickly identifying and addressing potential leaks, we can prevent contamination and demonstrate our commitment to sustainability. This not only helps us meet legal requirements but also enhances our reputation as responsible stewards of the environment.

In conclusion, the integration of advanced technology in pipeline monitoring is essential for maintaining safety, preventing leaks, and optimizing operational efficiency. From real-time data collection to predictive analytics, these tools are revolutionizing the way we manage our pipelines. So, let's embrace this technology and continue to push the boundaries of what's possible in ensuring the reliability and safety of our infrastructure.

Content expansion reading:

In the world of construction and engineering, where progress is often measured in miles driven by machines and hours spent on site, the importance of effective management cannot be overstated. This is particularly true for projects involving the installation of sophisticated tunnel monitoring systems. Such systems serve as crucial tools for ensuring the safety, reliability, and efficiency of underground infrastructure. By providing real-time data on various parameters such as traffic flow, temperature, pressure, and moisture levels, these systems can help engineers make informed decisions about maintenance needs, emergency responses, and even future expansion planning. In this guide, we will explore some key aspects of groundwork construction management that are essential for the successful installation of tunnel monitoring systems.

First and foremost, it is crucial to have a thorough understanding of the site's geographic and structural context. This includes identifying any existing structures, natural features, or hazards that may affect the placement and functionality of the monitoring equipment. For example, if the site contains active fault lines or areas prone to landslides, it may be necessary to relocate the monitoring stations or design them to withstand extreme environmental conditions. Similarly, if the groundwater table is higher than anticipated, it may require additional support measures to ensure that the equipment is not damaged or compromised during installation.

Another important aspect of groundwork construction management is communication. With so much information at play during each phase of the project—from initial site assessments to final installation and testing—effective communication is critical for ensuring everyone is on the same page. This means using clear and concise language when communicating with subcontractors, suppliers, and clients alike. It also involves being responsive to any questions or concerns they may have, and addressing them promptly. Additionally, maintaining a level of trust and transparency throughout the process is essential for fostering strong relationships and preventing misunderstandings.

When it comes to selecting the appropriate materials and components for your tunnel monitoring system, there are several factors to consider. First and foremost, you should choose materials that are durable, reliable, and long-lasting, which will help minimize downtime and reduce maintenance costs. This may include high-quality sensors, cables, and other electronic components that are designed to withstand extreme temperatures, vibrations, and other environmental stresses. You should also pay attention to the compatibility between different components, as failure to do so can lead to system malfunctions or damage. Finally, it may be beneficial to invest in specialized coatings or protective layers to enhance the durability and resistance of your monitoring equipment to harsh environments.

Installation is the next crucial step in ensuring that your tunnel monitoring system is up and running smoothly. This involves carefully positioning each piece of equipment according to its specifications, ensuring that they are securely anchored into the ground or structure they are intended to monitor. It may also involve drilling holes for cables or other wiring, installing switches and control panels, and connecting the various components together using specialized connectors and cables. During this process, it is essential to follow strict safety guidelines and protocols to protect workers from potential hazards or accidents.

After installation, it is important to thoroughly test your tunnel monitoring system to confirm that everything is functioning properly. This may include checking for errors or anomalies in readings from sensors or other devices, verifying that all connections are secure and functional, and ensuring that all alarms and notifications are activated and working as expected. It is also recommended to conduct regular maintenance checks and updates to ensure that your system continues to provide accurate and reliable data over time.

Finally, ongoing training and education is essential for anyone involved in managing or operating a tunnel monitoring system. This includes both technical staff who are responsible for installing or maintaining the equipment, as well as those who are responsible for analyzing and interpreting the data gathered by the system. By staying up-to-date with the latest developments in technology and best practices for data analysis, these individuals can ensure that their system is always operating at peak performance and effectively meeting the needs of their clients.

In conclusion, groundwork construction management is an essential component of any tunnel monitoring system project. By carefully considering various factors such as site context, communication, material selection and installation, testing, and ongoing training and education, you can build a system that is both reliable and cost-effective. Remember, investing in advanced monitoring technology today can save money in the long run by preventing costly repairs or emergencies down the road. So take the time to plan out your project carefully and execute it with precision, and you will be rewarded with a safer, more efficient underground infrastructure.

Articles related to the knowledge points of this article:

The Role of Comprehensive Monitoring Platforms in International Trade Operations

Environmental Impact Assessment for a Comprehensive Underground Utility Tunnel Project

Ensuring Safety and Efficiency in Underground Pipelines: The Role of Environmental Monitoring

Understanding the Role of a Conduit Monitoring Center in Modern Infrastructure

Why Monitoring Your Supply Chain is Crucial for Success

Ensuring Safety and Efficiency in Pipelines: The Key Points of Environmental Monitoring Systems